The Leatherman Blazer…innovative but is the juice worth the squeeze?

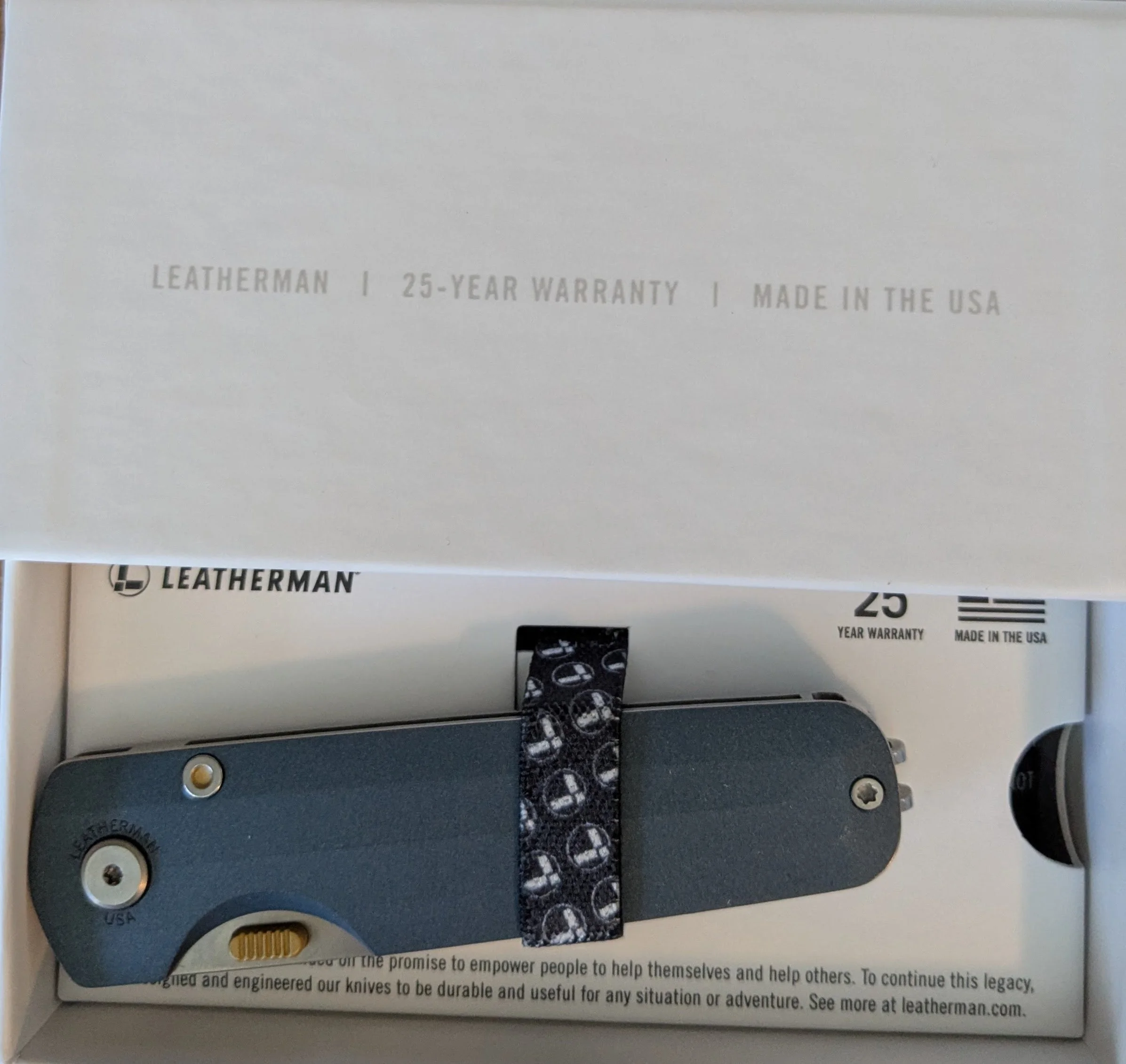

Today we are taking a look at the new Blazer folding knife from Leatherman. Traditionally known for their multitools they have previously made knives such as the Crater, a few Garage releases, and the Free K series not to mention the countless blades on their tools so they aren't totally new to the space. Not to mention the decades of manufacturing experience that comes from making multitools in the USA. How well does this all experience transition into making good every day carry knives though?

INNOVATION

Leatherman did some innovative things with this knife. There are no liners, no stop pin, no pivot nut, or many of the other parts you are used to seeing in your pocket knife. This was achieved by machining all of these parts into the stainless steel scales themselves. The scales are mated to one another and fit together perfectly.

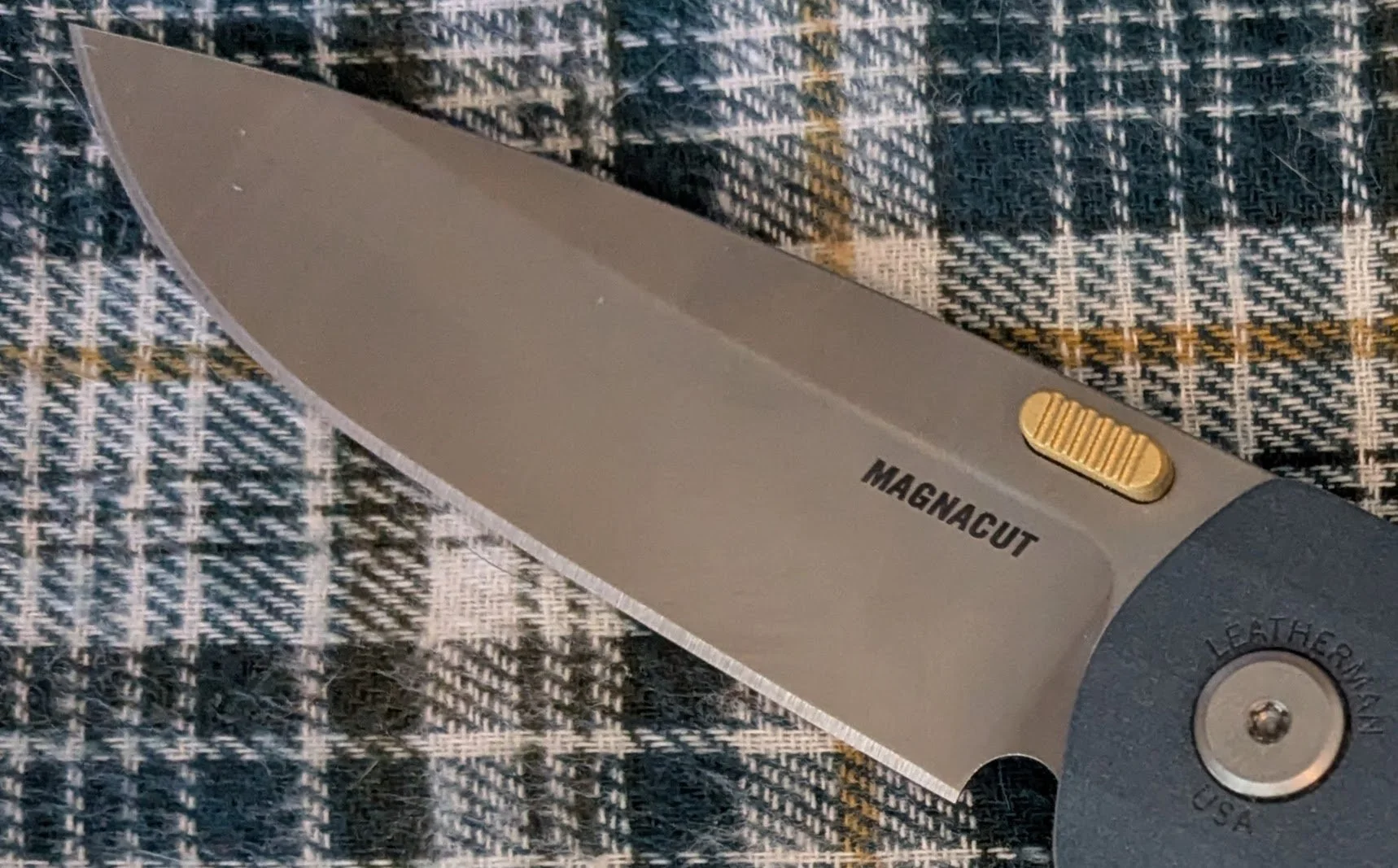

The locking mechanism is a new patent pending design by the company. It is similar to a button top liner lock but uses a block that sits between the blade and stop block on the scales. It's a very stable and solid lockup.

Overall the knife is made up of significantly fewer parts than a traditionally manufactured folder. This can help reduce tolerance stacking and with fewer parts interfacing reduce wear as well. It does bring up some concerns when anything at all fails and warranty work is needed. Stop block wears out? You are waiting on some newly machined and finished scales. Pivot nut strips? Newly machined and finished scales. My hunch is this ends up being like a Garage release after a few years with Leatherman not even attempting to fix them but just giving owners purchase price credit for a replacement.

MATERIALS

As they aren't living under a rock or hiding in a cave Leatherman knows the popularity of Magnacut and choose to leverage that for the blade on the Blazer. There are some gripes online about the range for the heat treatment and while the published specs aren't the most impressive my hunch is the actual blade themselves are in a tighter range based on the testing I have seen online so far. Their lack of confidence in that range enough pushing them to publish the wider spec is a touch concerning though.

The scales themselves are made of 416 stainless steel which isn't exactly impressive either, especially on a knife at this price point. I get it, they needed steel to be able to machine everything into them and reduce the parts count, but it still feels less than premium on a $300 knife. Top that off with the scales being finished with Cerakote which looks nice but wears like a suit from Goodwill and you lose some of the luster that they were trying to achieve here.

USABILITY

And then things took a turn….

While the Blazer is loaded with innovative ideas, generally good materials, and is executed at a high level the outcome of that is, well, a bad knife. The new locking mechanism, while having a smooth and polished opening, feels like you are operating a Gerber from the early 1990s. You have to control the blade fully into the open position and close it the same way. No flicking, no dropping shut, and none of the action you expect in a modern folder. In the first two days I successfully cut myself seven times trying to close it one handed. This isn't about fidgeting, this is about how we use knives today. I don't think most buyers are excited at the prospect of needing two hands to close a button lock folder.

The stainless scales are nice and thin but they are still heavy. The knife weighs over 20% more than a Knafs Lander 2 which is a similar size. Also the outer edges of the scales are polished and left unfinished. This looks nice but makes the knife slick. It's very difficult to get out of the pocket and, worse, it slides around in your hand when wet. The only reason you have any control at all if you are sweating or bleeding is the finger cutout.

The entire things comes across as them having looked at four aspects during usability testing…does this function, does this stay together well enough to minimize warranty work, is this safe enough to not get us sued, and does this look good on Instagram. That's it. There is simply no way someone used this extensively and said they were on the right track. The only thing I can see is that they are judging how this operates against the knives on a multitool and choose to make it function the same way. I can understand the logic if that is the case but it shows a severe lack of understanding of the EDC knife market today.

What does this mean for Leatherman?

Is this going to be the game changer Leatherman is betting on? No, no I don't think so. The only positive reviews I am seeing are from people who didn't have to buy the knife themselves with their own money. Reading across social media it looks like a tie for what is more popular…the new Leatherman knives or COVID. The company’s response to all of this has been a strong campaign of simply ignoring the outrage and that just feels like a bad approach to me. Folks keep saying the market was begging for this but I am not buying it. No one asked for this. Maybe knives from Leatherman…maybe even Magnacut…but $300 knives that don't drop shut? Come on, stop insulting your customer base and admit you goofed on this one.

The problem here is that Leatherman bet big on this. They opened a facility, they bought machinery, they devoted marketing dollars and a lot of them. Clearly they are expecting this to be a big line for them and maybe the next round of products, assuming they listen to their customers, will be. But if they need to make a significant return on this release to keep operations going they may be in trouble.

Leatherman could benefit from taking a look at how Hogue entered the knife market. They made products using features that the market wanted, they held to a premium standard, and they were priced within reason for those products. They should also look at WorkSharp’s release of the RMX. That knife includes many innovative solutions as well but they are all geared towards results that improve the user experience. The RMX reduced weight, reduced the parts count while simplifying repairs, and kept the price in line for the product. Its a pattern that works and I hope to see Leatherman learn from that for the next release.

My 2 Cents…

As a huge fan of the brand and a Leatherman tool user for decades this release leaves me with some mixed feelings. On one hand they did some innovative things, showed off some amazing manufacturing skills, and did deliver on their statement that these are “built different”. But on the other hand its just not a good knife and, Magnacut aside, this $300 product is outclassed in nearly every way by a $60 Kizer Drop Bear 2. I am happy to have it in my collection , I am happy to support American manufacturing, and I like seeing them try new things but I think they looked at all of the new techniques and materials they could use without stopping to ask if they should use them. Its a knife I will enjoy owning but will likely never carry again after this review. Yes, they are built different…but does that really mean built better? At least for me that answer is a resounding no.

Remember all, enjoy your EDC!